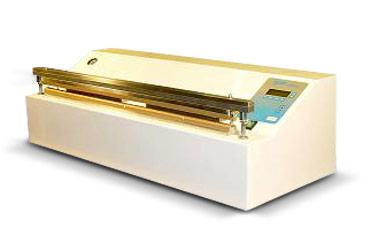

- Gantry type sealer available in widths from 1000mm – 3000mm

- For sealing PU coated fabric, woven Polypropylene, non woven Polypropylene, anti vandal material and stab vest fabric

- Precise control of sealing and cooling temperatures to +/-1% accuracy across the full length of the 6mm wide sealing wires, with no hot spots. Fully validatable.

- Compatible with low expansion sealing wire

- Fast, repeatable and consistent

- Robust aluminium construction

- Free standing to any operating height, or bench mounted

- Jaw spacing 50mm – 200mm

- Foot pedal or twin push button operation with fully integrated safety circuit

- Made in England with all British and European components

Hospital mattress & pillow medical gantry sealer

Audion MagVac MED medical Vacuum Sealer

- Audion Power Sealer 520mm, 720mm and 1020mm Validated medical bag sealing

- 8mm weld width

- Validation of seal time, seal temperature and seal pressure

- Multi cycle gas flush for modified atmosphere packing

- Both jaws heated for sealing laminates and thick pouches

- 9 programs to store all settings for different bags

- Very user friendly digital Resistron control

- Pneumatic operation for very strong sealing and long term reliable operation

- Self contained vacuum pump

- Designed for clean room operation. Medical vacuum sealer video

- Also available as non vacuum Audion Power Sealer IST Med

Options:

- Horizontal or vertical operation with the optional floor stand

- Bag stretch unit to maintain a crease free seal for large bags or tall products. Magvac medical bag stretch option video

- Bag support

- External vent

- Full calibration service with traceable calibration certificate

- Data upload

| Model | Magvac 520 MED | Magvac 720 MED | Magvac 1020 MED |

|---|---|---|---|

| Sealing Jaw Width | 520mm | 720mm | 1020mm |

| Element Width | 8mm | 8mm | 8mm |

| Power Requirement | 230V Single Phase 50/60Hz | 230V Single Phase 50/60Hz | 230V Single Phase 50/60Hz |

| Pneumatic Requirement | 6 – 8 Bar | 6 – 8 Bar | 6 – 8 Bar |

Star Medical Sealer

- Developed specifically for the Medical and Pharmaceutical Industries where accurate control of weld quality is required for validation

- PLC controller continually accurately measures the sealing jaw temperature compensating for any deviation from the set temperature.

- Seal time is measured to the tenth of a second along with the pneumatic pressure.

- One or both jaws heated with separate temperature settings

- Pneumatic operation to give consistent seal pressure

- Full calibration and validation available

- Multi level password protection of settings

- 10 pre-set parameters with alphanumeric description

- Batch counter

- Cycle data stored for uploading onto spreadsheet

- Suitable for use in a clean room

- Seals a wide range of thermoplastic films/laminates including Tyvec

Options:

- Automatic flying knife-cutting system

- Optional constantly heated sealing jaws

- Twin parallel welds

- Water cooled sealing jaws

| Model | MS400 | MS600 | MS800 |

|---|---|---|---|

| Sealing Jaw Width | 400mm | 600mm | 800mm |

| Element Width | 9.5mm | 9.5mm | 9.5mm |

| Cutter Option | Flying Knife | Flying Knife | Flying Knife |

| Power Requirement | Single Phase 13A | Single Phase 13A | Single Phase 13A |

| Pneumatic Requirement | 6 – 8 Bar | 6 – 8 Bar | 6 – 8 Bar |