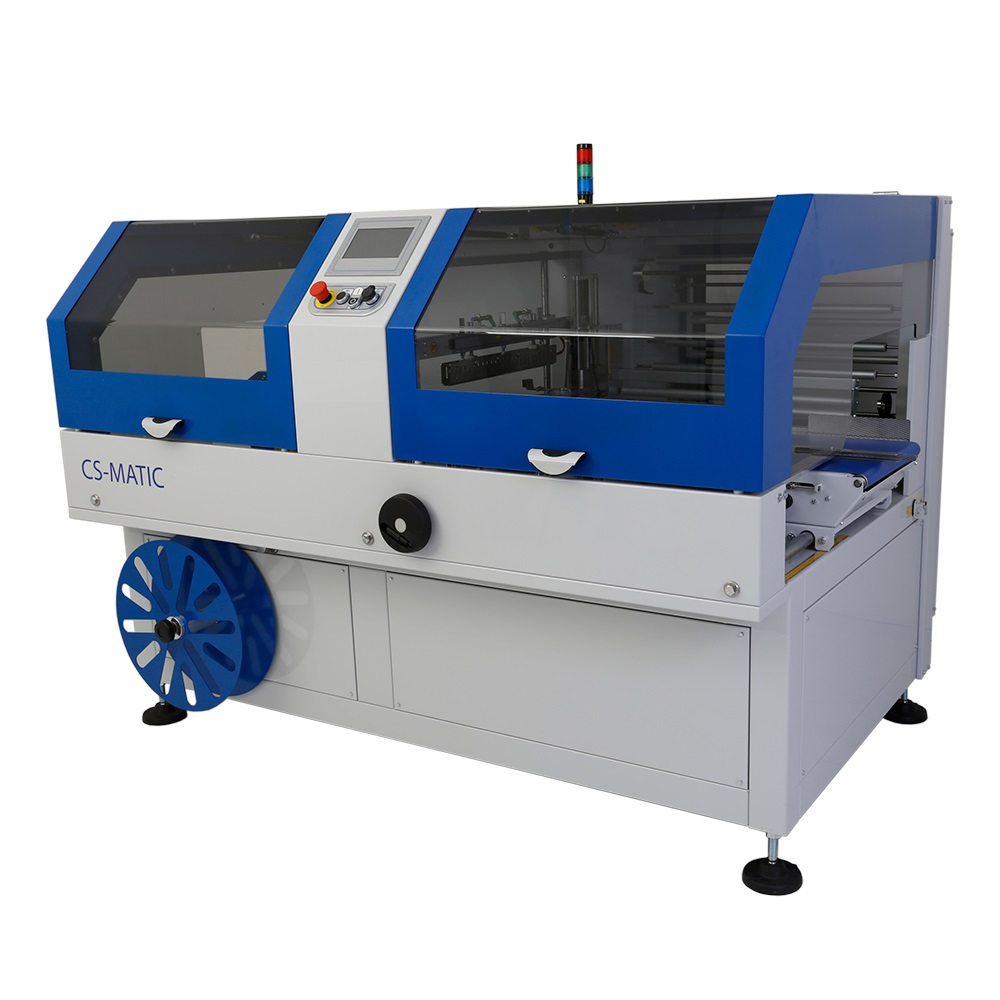

Mac Due Utility Automatic Sidesealers

- For shrink wrapping or bagging products in polythene shrink wrap films

- Capable of handling product up to 6000mm long

- Constant heat transverse sealing blade with longitudinal sealing wheels

- Variable speed infeed and discharge conveyors

- Siemens plc controls all major functions

- 3 models available: Utility 50 500mm, Utility 80 800mm and Utility 120 1200mm

Utility 120 side sealer widely used for bagging building insulation materials in coloured polythene films.

| Model |

Utility 50 Side Sealer |

Utility 80 Side Sealer |

Utility 120 Side Sealer |

| Min. Product Size (LxWxH) |

150mm x 80mm x 30mm |

150mm x 80mm x 30mm |

150mm x 300mm x 50mm |

| Max. Product Size (LxWxH) |

6000mm X 380mm X 300mm |

6000mm X 600mm X 370mm |

6000mm X 1000mm X 400mm |

| Power Requirements (Side Sealer) |

3 Phase 16 amp |

3 Phase 16 amp |

3 Phase 16 amp |

| Power Requirements (Shrink Tunnel) |

3 Phase 40 amp |

3 Phase 50 amp |

3 Phase 60 amp |

| Pneumatic Requirements |

6 – 8 Bar |

6 – 8 Bar |

6 – 8 Bar |

Bespoke Range

If the standard range does not satisfy your requirements we have a range of high speed wrappers to satisfy all speeds and product sizes. Please ask us for more information. Contact our machinery sales department on

01274 872299 or sales@sontex.co.uk